East China’s Jiangsu province has spared no effort to promote the high-quality development of new energy and dual-carbon industries by taking project construction as the keel and leading enterprises as the driving force.

In the exhibition hall of a New Material Technology Co., Ltd. in Nantong, a white felt cloth made of aerogel material looks unremarkable. The blue-blue flame from the spray gun continued to burn, but the felt cloth did not show any flames. There is almost no change in the parts, and there is no heat in the back.

Aerogels, the lightest solid material known as "blue smoke", are super-insulating materials that are increasingly used.

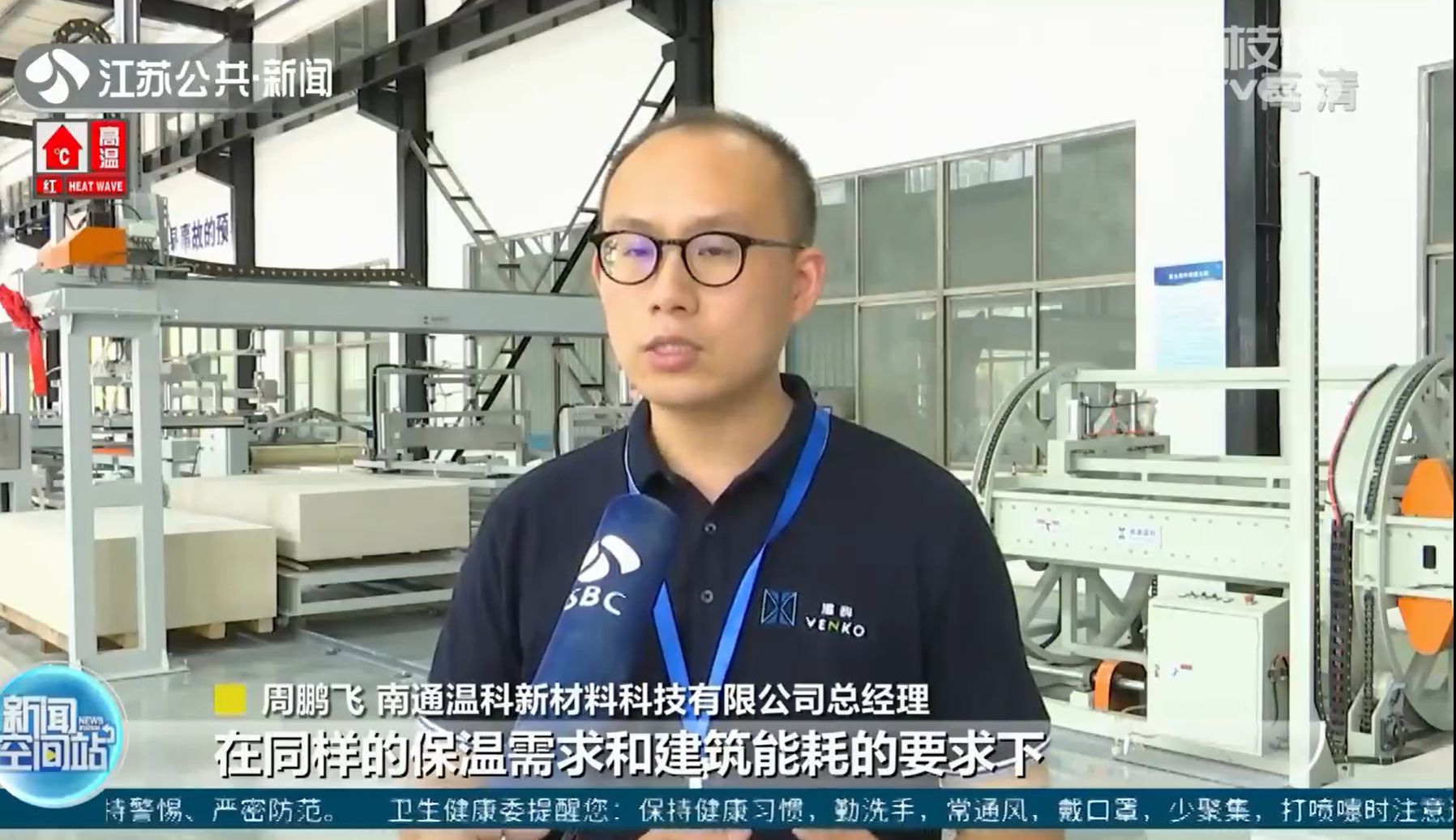

China’s first domestic aerogel composite board production line was put into operation in Rugao County recently. Expected to produce 800,000 to 1,000,000 square meters in annual productivity, the production line will produce eel composite board to be used in various large public buildings such as hospitals, laboratories, libraries, and schools.

Zhou Pengfei, General Manager of Nantong Wenke New Material Technology Co., Ltd.

In the early days, aerogel relied on imports, and now it has been industrialized in China.

XCMG's pure electric battery swap dump trucks can realize quick battery swap in three to five minutes depending on the supporting swap station, saving 4 million liters of diesel per 100 vehicles per year and reducing carbon emissions by 12,500 tons.

For future development, XCMG will focus on pure electric vehicles, hybrids, fuel cells, as well as multi-energy powertrain control systems, drive motors and power batteries.

Luo Donghai, Deputy General Manager of XCMG Group, Secretary of the Party Committee of XCMG Automobile, General Manager

As of the end of June, Xuzhou reported a 54.5% year-on-year increase in the output value of the new energy and dual-carbon industries, including a 76% year-on-year increase in the output value of the new energy industry.