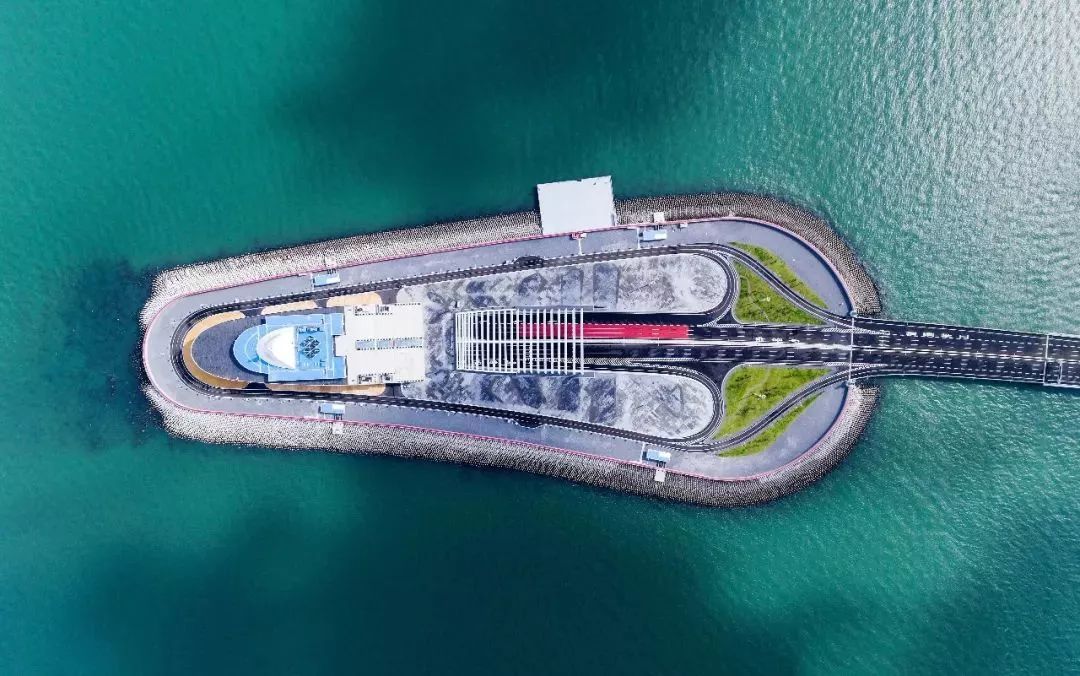

The Hong Kong-Zhuhai-Macao Bridge has just opened to traffic Wednesday morning.

The Bridge, with a total length of 55 kilometers, connects Hong Kong, Zhuhai and Macao, and combines bridge, island and tunnel as an entirety. It is the bridge that is longest and requires highest technology of construction in the world. Therefore, the Hong Kong-Zhuhai-Macao Bridge was reported by the Guardian as one of “The Seven Wonders of the Modern World”.

We have much to be proud of since the Bridge shines with many “Jiangsu elements”.

Overlooking from Zhuhai to Lingdingyang Sea, people can see the two white sail-shaped steel towers on the Jiuzhou Channel Bridge which are called “the landmark of landmarks”, and these two towers are produced by China Railway Turnout Bridge Inc in Yangzhou City.

The final joint is the control junction of the bridge and tunnel. It is the key component produced in Nantong. The Zhenhua Company in Nantong initiated a final joint and a butt construction method for an immersed tube tunnel instead of the traditional foreign construction method, which is the first application of the “integral prefabricated installation” worldwide.

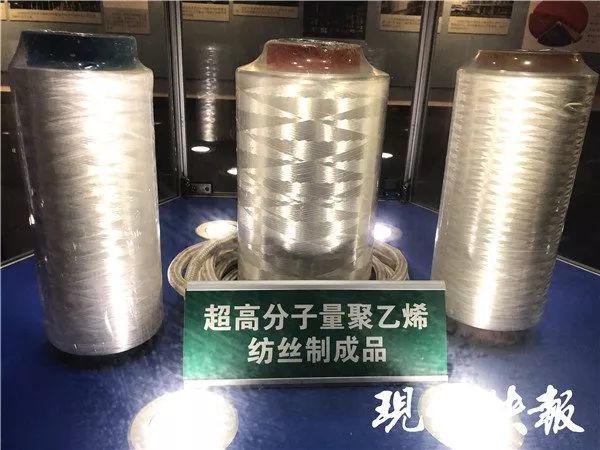

The high-performance rope developed by Sinopec Nanjing Research Institute of Petrochemical and China Textile Academy facilitated the hoisting and closing of the Hong Kong-Zhuhai-Macao Bridge. The thickness of the rope is only one-tenth of that of a single hair, but it is three times as strong and intense as steel of the same thickness.

Many alumni from universities of Nanjing have participated in the construction of the Bridge, such as the general manager and chief engineer of the island-tunnel project, Lin Ming, is an alumnus of Southeast University.

During the process of researching and developing, Lin Ming and his team met unimaginable difficulties since they had little foundation. The difficulty of constructing a submarine channel of 6.7 kilometers at a depth of 50 meters underwater is no less than threading a needle under the sea.

Liu Xiaodong, the deputy general manager and chief engineer of construction drawing design of the island-tunnel project, is graduated from Southeast University.

On May 6, 2013, the first immersed tube was successfully connected with the buried section of the west artificial island, which completed the first joint under the sea. About four years later, on March 7, 2017, the construction of all the 33 immersed tubes was completed. The Bridge became a realization of Liu Xiaodong’s design paper.

A number of alumni of Hohai University who work in CCCC Fourth Harbor Engineering Co.Ltd., CCCC Fourth Harbor Engineering Institute Co.Ltd., China Harbour Engineering Corporation and Nanjing Hydraulic Research Institute have made outstanding contributions to the scientific research, construction and management of the project.

For example, Zhu Lixiang, a 1984 Hohai Uiversity graduate of port and waterway engineering major, is the Party committee and chairman of CCCC Fourth Harbor Engineering Institute Co.Ltd. The corporation focused on the large cylinder construction technology applied in the Yangtze River estuary project and Nansha port project, and came up with the design scheme of making the large cylinders quickly form an island. It led to the quick completion within one year of the construction of the east and the west artificial islands, which had been planned to be completed in 2-3 years.

Furthermore, many other corporations also contributed a lot to the construction of the Hong Kong-Zhuhai-Macao Bridge.

Sinopec Nanjing Research Institute of Petrochemical. The thickness of the rope is only one-tenth of that of a single hair, but it is stronger than steel of the same thickness.

Nanrui Group Co.Ltd. The fire prevention of the 140 transformers reaches the foreign indoor standard.

In 2016, Nanrui Group Co.Ltd. received an order of buried transformer that is worth 16,850,000 yuan from The Fourth Engineering Co.Ltd. of China Railway Construction Electrification Bureau Group, which took over the transportation engineering of the Bridge. All the transformers were customized for the Bridge. The width of the same kind of transformer is 1.2-1.3 meters, while the width of a customized one is 1 meter.

Jiangsu Transportation Research Institute Company Limited used the ruler of millimeter to ensure the safety of the Bride.

From 2011 to 2018, the team of Jiangsu Transportation Research Institute Company Limited has spent 8 years to take charge of materials, structural performances and construction management. The members have spent their youth and witnessed the completion of the Hong Kong-Zhuhai-Macao Bridge.

The west artificial island. (Picture/ the Hong Kong-Zhuhai-Macao Bridge Administration)

Led by the academician in Jiangsu Sobute New Materials Co.Ltd., the team conducted more than 100 performance tests to make the concrete more solid and durable.

The team of Jiangsu Sobute New Materials Co.Ltd. which was led by academician Miu Changwen, has contributed 7 years to the construction of the bridge. During the process, they had held dozens of seminars and conducted more than 100 performance tests. The polycarboxylate superplasticizer products ensured the durability of concrete and stability of its performance. The company designed customized products according to actual conditions. Meanwhile, it provided technology service and support for the Hong Kong-Zhuhai-Macao Bridge construction organization all the way.